Sidewalk Maintenance and Repair

/December 2015

by Bill Christenson

Many of our residential neighborhoods and most municipal business districts have sidewalks along public right-of-ways providing public access throughout our communities. Commonly, sidewalks are constructed with public funding by municipalities or as part of private site developments. The general perception may be that maintenance and repair of these sidewalks is the responsibility of the city in which they are located, though this is not necessarily the case.

Many of our residential neighborhoods and most municipal business districts have sidewalks along public right-of-ways providing public access throughout our communities. Commonly, sidewalks are constructed with public funding by municipalities or as part of private site developments. The general perception may be that maintenance and repair of these sidewalks is the responsibility of the city in which they are located, though this is not necessarily the case.

The Revised Code of Washington (RCW) Chapter 35.69 allows city councils to place the duty, burden, and expense of sidewalk maintenance and repair upon the property owner directly abutting the improvement. Several of our local cities including Seattle and Tacoma have adopted resolutions that require property owners to maintain sidewalks fit and safe for public travel. The Seattle Department of Transportation and Tacoma Public Works Department identify several conditions for sidewalk repairs including:

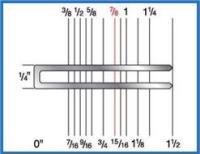

· Height differential or separation greater than ½”

· Cracks, separation, or hole greater than 1” in width

· Any piece of sidewalk that can be moved with ordinary foot pressure

· Undermined sidewalks

Sidewalk repairs may include concrete grinding, slab jacking, filling of cracks and holes, tree root maintenance with an authorized arborist, or complete removal/replacement of damaged walks. Repairs must also be performed in accordance with city current standards. Most repairs will necessitate hiring a competent concrete contractor.

Typically sidewalk damages caused by city trees are the responsibility of the city. The City of Seattle maintains an inventory of “city” trees that can be viewed at http://www.seattle.gov/transportation/treeinventory.htm. Sidewalk damage caused by private trees may be the responsibility of the property owner.

Be aware that as an owner of commercial or residential property in Washington State, you may be responsible to keep the adjacent sidewalk properly maintained and repaired. Check with your local municipality regarding sidewalk maintenance and repair requirements in your city.